Project overview

Bringing Green Chemical Production Forward in Central Europe

The chemical industry in central Europe struggles with excessive waste, high greenhouse gas emissions, and a strong reliance on petroleum-based materials. The GreenChemForCE project helps companies to change production processes from linear production streams to circular systems. The partners test new technologies that reduce hazardous solvents and reuse remaining ones. They also develop a strategy for the production of greener chemicals and train a wide range of companies on how to apply them to clean up the sector.

-

1,77m €

-

Project Budget

-

80%

-

of the Budget is funded by ERDF

-

4

-

Countries

-

5

-

Regions

-

9

-

Partners

-

4

-

Pilots

Duration

Start date

End date

Project progress

Project partnership

Project partners

Lead partner

Charles University

Department of Organic Chemistry, Faculty of Science

Project partner

102 37 Praha-Dolní Měcholupy

Kémiai Intézet

Institute for Applied Synthetic Chemistry

Faculty of Chemistry and Chemical Technology

1030 Wien

Roadmap

Context

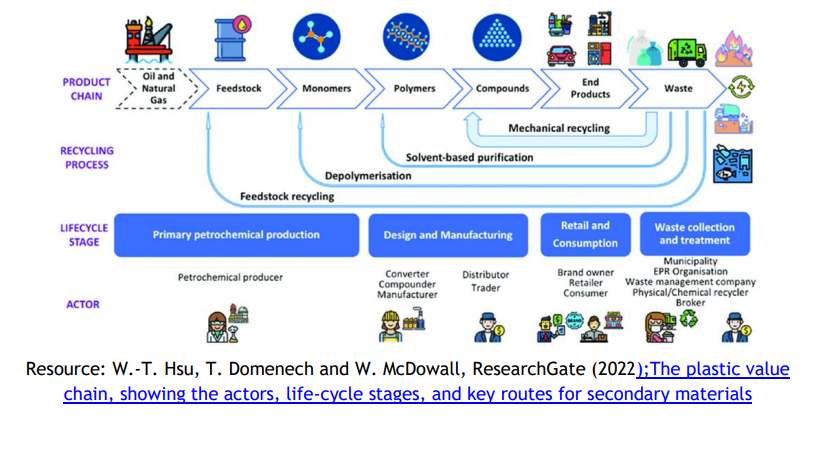

The chemical industry in Central Europe is a major economic driver—but also a significant source of environmental pressure. It traditionally operates within a linear model: extract resources, produce, and discard. To support the EU’s climate and circular economy goals, the GreenChemForCE project brings together public, private, and academic actors to accelerate the transition of the chemical sector from linear to circular production systems.

Specific Problem

Central Europe’s chemical sector faces several interlinked challenges. High greenhouse gas emissions, heavy reliance on petroleum-based raw materials, and the generation of hazardous waste, such as used solvents and non-degradable plastics, pose serious environmental threats. These practices also contribute to negative public perception, hinder innovation, and reduce long-term competitiveness. A systemic change is needed to make the industry more sustainable and resilient.

Idea

GreenChemForCE is building a transnational knowledge and innovation network focused on chemical circularity. We unite experts in chemical recycling, CO₂ recovery, green solvent use, and sustainable synthesis—along with industrial stakeholders from pharmaceuticals, textiles, and other chemical-intensive sectors. This network enables us to identify critical transformation points and co-create solutions tailored to real-world industrial needs.

Solution

Our approach works on two levels. Strategically, we map the state of the sector, highlight barriers to circularity, and define action-oriented roadmaps. Practically, we collaborate with companies to test new green technologies—such as alternative solvent systems and closed-loop material recovery. Through joint pilot projects, cross-sector training, and industry-academia exchange, we ensure that innovation reaches the market and contributes to measurable environmental improvement.

Implementation

The project consortium includes universities, research institutes, public bodies, and private companies active in Central Europe's chemical and related industries. Each partner contributes its expertise to pilot actions, workshops, and demonstration activities. Industrial partners, including pharmaceutical and textile producers, will lead the real-world testing of greener production methods and play a key role in mainstreaming circular practices within their sectors.

News

Events

Pilot actions

Outputs

Work Packages

1. Analysis of the current state and new strategies for sustainable development

2. Development of sustainable technologies for key plastic components and circularity in plastic production

3. Analysis of carbon dioxide linear and circular

4. Technologies towards atom circularity in CO2 management

5. Current state analysis and strategies towards greener fine chemical production

6. Technologies towards reduction of waste solvents and other critical materials

7. Advanced technologies towards effective processes

Project documents

NEWSLETTER

EVENTS

GreenChemForCE

The project lead partner is responsible for the content of this project website.