As long as value is only created through the sale of new products, new products are constantly being sold that are neither repairable nor durable. It is crucial for companies to develop the right circular business model that also recognizes, uses and preserves the embedded value in the product.

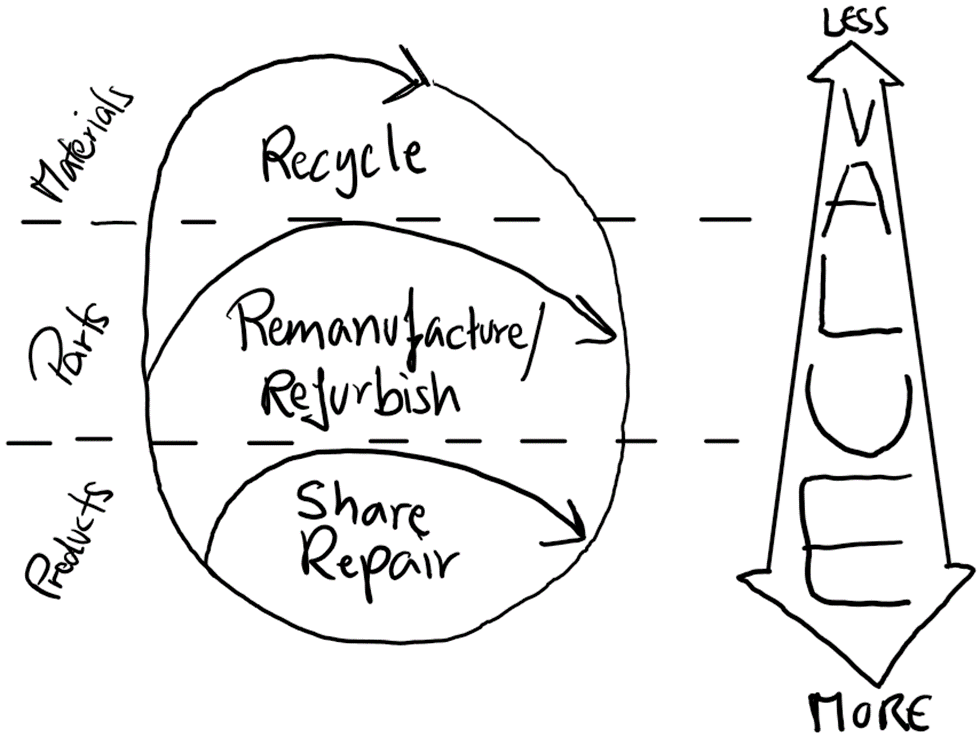

The materials in the product components have value, the components in the product have value and the entire product has value. Recycling only recovers the value of the materials, which should be the last step in the circular economy. Before that, one should think about how to best utilize the value of the product and its components and not destroying them in a shredder where they only open choice is recycling. The key words are repair, reuse, repurpose, remanufacture and refurbishment.

Try to keep products and resources in the smallest cycle as possible by generally reducing the need for products, sharing products, reusing unused products for other purposes and repairing them before they are thrown away. If, for whatever reason, the product cannot be kept and reused as a whole, try to use the value in the next level, the component cycle, for as long as possible.

Can’t a company even benefit from not selling the product instead of providing the function of the product as a services, e.g. clean laundry instead of a washing machine? Suddenly the manufacturer would have an incentive to supply a product that is durable and repairable as they retain ownership of the product. This keep the product in the shortest cycle, saves resources, reduces waste and reverse logistics would also be easier.

Written by: Philipp Feuchter, Vienna University of Technology