Project overview

REshaping Central Europe IndUstry Sustainability through circular Economy models by 2030

The manufacturing industry in central Europe uses a lot of resources but recycles only 12%. To improve circularity, waste streams need to be better understood and new solutions developed. The REUSE2030 project analyses current waste streams and circular practices in the mechanical sector. This leads to a new digital circular inventory, which empowers mechanical companies to autonomously choose sustainable practices. The inventory is complemented by a newly developed zero carbon toolkit. Both tools are tested in companies and inform a new strategy with circular solutions to reduce the mechanical sector's waste streams.

-

2,19m €

-

Project Budget

-

80%

-

of the Budget is funded by ERDF

-

9

-

Countries

-

10

-

Regions

-

10

-

Partners

-

2

-

Pilots

Duration

Start date

End date

Project progress

About the project

Project partnership

Project partners

Lead partner

ECOLE – Enti Confindustriali Lombardi per l'Education SCARL

Project partner

European Campus Rottal-Inn

95-050 Konstantynów Łódzki

Roadmap

CONTEXT

The mechanical sector, a cornerstone of the Central European economy, generates significant export volumes but faces growing challenges in waste reduction and recycling due to the complexity of products and the presence of hazardous materials. Amid disparities in infrastructure across countries, the project aims to promote circular economy models to support sustainability and innovation in the sector.

MAIN PROBLEMS

- Large amounts of waste generated by the mechanical sector. - Significant differences between countries in the capacity to implement circular economy solutions. - Lack of digital tools to support SMEs in adopting sustainable practices. - Barriers to creating transnational networks for sharing solutions

OUR CHALLENGE

REUSE 2030 WORKS to overcome infrastructural disparities and increase the adoption of circular economy principles in mechanical SMEs across Central Europe. Through innovative digital tools and transnational collaborations, we aim to reduce waste and improve sustainable product design, contributing to the EU’s 2030 climate goals

SOLUTIONS

- Digital Circular Inventory: An app that helps companies identify circular economy solutions based on their waste streams. - Zero Carbon Toolkit: A tool for self-assessing carbon footprints and optimizing production processes. - Transnational Strategy: Fostering cooperation among universities, chambers of commerce, and development agencies to implement practical solutions. - Capacity Building: Training programs to accelerate the adoption of circular models

News

Events

Outputs

0 1.2 REUSE2030 Transnational Strategy

O 2.1 Testing of a Digital Circular Inventory for circular economy solutions

O 2.2 Testing of a Zero Carbon Tool supporting mechanical industry

O 3.1 Circular Economy tailor – made solutions from Digital Circular Inventory

O 3.2 Zero Carbon Tool product design and production optimization tailor -made solutions

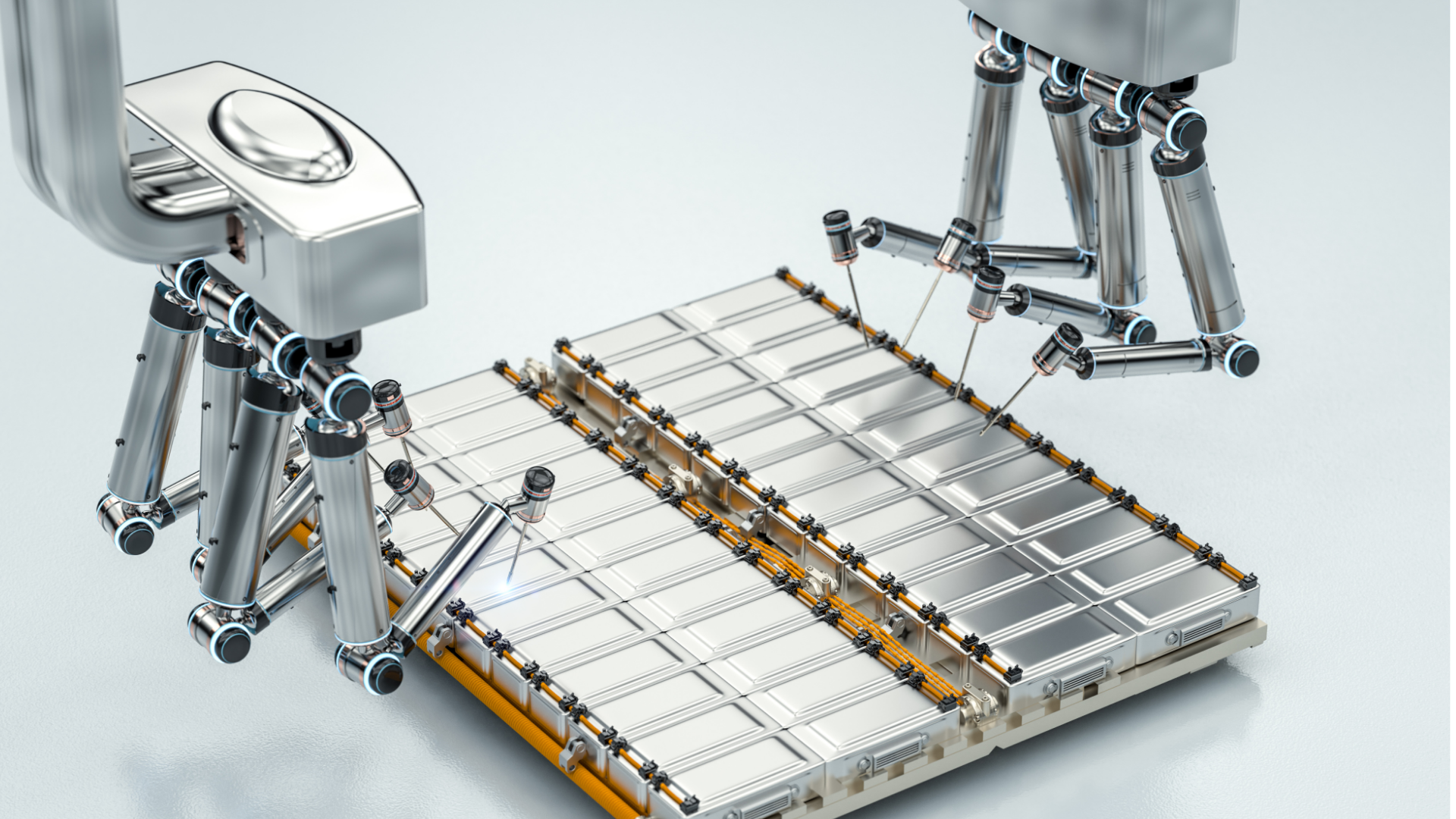

Project images

REUSE2030

The project lead partner is responsible for the content of this project website.